X-ray crystallography

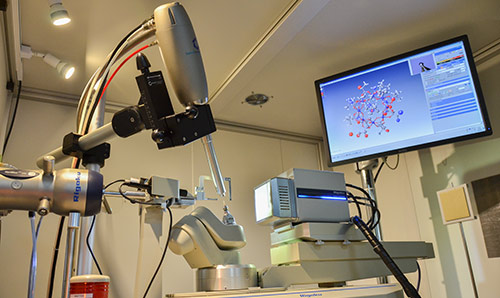

The X-ray crystallography suite is located in room 5.62 in the Chemistry Building and provides both single crystal and powder diffraction facilities.

These facilities are for use by staff, students and commercial customers. We currently have six X-ray diffractometers capable of collecting data for single crystal collections, powder XRD and small single X-ray scattering (SAXS) measurements.

For single crystal diffraction we can provide a walk up service from data collection through structure determination and refinement to a completed CIF file, to full training for self collection, solution, refinement and final CIF creation.

For powder XRD we can provide training in operation of the two diffractometers and advise on collection parameters and interpretation of results.

The SAXS is an industry-leading instrument and training can be provided in it is operation; limited assistance is available for interpretation of results.

Crystal production and presentation

- The crystals should be produced as slowly as possible to increase the probability of 'good' crystals. 'Good' includes being of a reasonable size, 0.2-0.5mm (less if heavy elements are present), clear and uncracked with well defined edges and faces. Sufficient characterisation should be carried out to verify that, at least, the crystal is not starting material or a previous structure.

- Where the crystals are only stable in their mother liquor, for preference the solvent(s) used should be as non-volatile as possible and non toxic, as the solvent will tend to evaporate during examination.

- As far as possible the sample should be pure.

- Make your sample is 'available' ie extractable. Narrow bore vials, small numbers of small crystals, especially in excess mother liquor will make extraction difficult, as will screwtops, by introducing grooves at the top of the vial.

- Fill in an application form CRS Application for X-ray Crystal Structure Determination giving chemical, structural, toxicological etc. data about the crystal. If the sample is toxic safe handling procedures should be indicated.

- Deliver to 6.24.

Because of the diverse and often unknown chemical, toxicological and radiological nature of the material, contaminated material, typically wipes and microscope slide(s), may be returned, as well as the residual 'crystals'.

If you wish to do the data collection yourself it would usually be at weekends. As a first step, contact your supervisor to arrange training.

Troubleshooting

Solution

Having tried SHELX(S), SIR2004, (SUPER)FLIPPER(WinGX) etc to no avail and before badmouthing the chemist for really not trying, re-examine:

- Data: Weak(I/sigma(I) < 1 is going to be a challenge)

- Composition: A badly incorrect formula can throw out many direct methods programs; some charge flipping programs are more resistant as they use Fs and not Es

- Cell: Danger signs include:

- Large number of reflections not 'explained'

- Easily changeable cell

- Unexpectedly large cell

- Uncommon crystal system: most common S.G.s:P21/c, P-1, P212121, C2/c, P21, Pbca, Pna21, Cc, Pbcn and C2

Cell_now may be of assistance, even when non-merohedral twinning, for which it was designed to find, is minimal or absent.

cell_now [1.p4p](loaded with selected rlps)

---

From the selection of cells produced choose one (usually the first, but may prefer eg 'higher symmetry' other). This is used to index the rlps in various orientations; a (multiple) p4p file is written after each and RLATT(current .p4p file) can be used to view colour coded rl:white rlps indexed by first component, green by current component and red are unindexed; an analysis shows how many are unique to each orientation, how many composite and how many left.

Refinement

- Disorder: The implicit model should be chemically plausible; eg: bent phenyl rings aren't. Working on the principle that 'Nothing succeeds like excess' W(hole) M(olecule) D(isorder) may be allowable. This illustrates the use of the FRAG facility in SHELXL taken to this extreme. Have the right bits in each PART; swapping may help(see s2512)

- Twinning: If not apparent at the indexing stage, the |E**2 - 1| statistic should give a clue as does the presence of METRICALLY higher symmetry cells, both of which may be found in XPREP. Pseudo-translation CAN be indicative but may be just indicating centring etc.

- RTFM SHELX and see if any of the 'recipe' matrices apply

- Use WinGx to run one of the twinning programs to generate matrices and HKLF5 data

- Heroically do it by hand: eg: if metric symmetry is higher than the actual as in Orthorhombic instead of Monoclinic,to see if a non-monoclinic operation(nm-op) is causing the problem: [O2M].[nm-op].[M2O]. Mathematica may be found useful.

- Collecting data at a different temperature may help, ie closer to the preparation temperature to minimise the probability of any phase change.

Extras

Checklist

Check ADPs for high/low/NPD values.

Re-label atoms to final values and sort before adding Hs.

If chiral with a high sd of the Flack parameter, merge the Friedel pairs(MERG 4 in SHELX)

Run checkCIF.

Fragments

FRAG 17 1.57 1.57 1.57 90 90 90

#PF6

P1 0.0 0.0 0.0

F1 0.0 -1.0 0.0

F2 1.0 0.0 0.0

F3 0.0 1.0 0.0

F4 -1.0 0.0 0.0

F5 0.0 0.0 -1.0

F6 0.0 0.0 1.0

FEND

FRAG 17 6.1269 14.6159 12.6541 90 103.228 90 (ACERAC)

# (CH3)2NC=O:(Dimethyl Formamide DMF)

C8 1 0.096400 0.094890 0.319840 1.000000 0.05000

O3 4 -0.087730 0.060150 0.321010 1.000000 0.05000 #cis to C9

N1 3 0.175730 0.103760 0.231480 1.000000 0.05000

C9 1 0.048500 0.072200 0.126620 1.000000 0.05000

C10 1 0.392900 0.145430 0.234700 1.000000 0.05000

FEND

#(CH3)2C=O:acetone

FRAG 17 7.884 10.5648 24.6438 90 90 90 (ABEGUK)

O7 4 0.495600 0.811900 0.176790 1.000000 0.05000

C19 1 0.467300 0.876600 0.216690 1.000000 0.05000

C20 1 0.550400 1.002600 0.223430 1.000000 0.05000

C21 1 0.349200 0.834100 0.260300 1.000000 0.05000

FEND

#!CH3NO2

FRAG 17 10.331 6.322 8.52 90 90 90 (ADEZUF)

C2 1 0.809000 0.861000 0.714600 1.000000 0.05000

N1 3 0.813600 0.710300 0.579300 1.000000 0.05000

O1 4 0.887600 0.748200 0.472500 1.000000 0.05000

O2 4 0.742800 0.556800 0.582800 1.000000 0.05000

FEND

#!CCL2

FRAG 17 7.9711 8.3909 9.5169 99.1945 108.748 110.617 (ACIWOY)

C22 1 0.654200 -0.205400 -0.443100 1.000000 0.05000

Cl1 5 0.718700 -0.366390 -0.377580 1.000000 0.05000

Cl2 5 0.457300 -0.303900 -0.626600 1.000000 0.05000

FEND

#!Et2O

FRAG 17 16.648 17.329 27.222 90 101.753 90 (BEMJOT)

C81 1 0.537600 0.525800 0.196670 1.000000 0.05000

C82 1 0.548800 0.518900 0.252330 1.000000 0.05000

C83 1 0.475800 0.519900 0.317730 1.000000 0.05000

C84 1 0.393000 0.539300 0.328930 1.000000 0.05000

O13 4 0.471940 0.530420 0.265750 1.000000 0.05000

FEND

#!MeCN Need at least three atoms but what if one is zero occupancy?

FRAG 17 13.489 28.657 15.063 90 116.552 90

C53 1 -0.848800 1.328150 -0.307500 1.000000 0.05000

C54 1 -0.756600 1.333230 -0.331200 1.000000 0.05000

N9 3 -0.684500 1.337600 -0.349900 1.000000 0.05000

FEND

#Pivolate->acetate as Mes position is uncertain(CEBZEP)

FRAG 17 11.0624 16.4631 15.3066 90 92.591 90

O1 3 0.136590 0.153720 0.322840 1.000000 0.05000

O2 3 0.131980 0.131600 0.463340 1.000000 0.05000

C1 1 0.185030 0.123740 0.392660 1.000000 0.05000

C2 1 0.305400 0.078190 0.391400 1.000000 0.05000

# Mes

C3 1 0.367900 0.096100 0.308600 1.000000 0.05000

C4 1 0.381500 0.100900 0.473100 1.000000 0.05000

C5 1 0.276700 -0.013000 0.396800 1.000000 0.05000

FEND

# tert-butyl: C1 bonds to rest of moiety. Coors set so z is bond length;1.54 is default for all

FRAG 17 1 1 1 90 90 90

C1 1 0. 0. 1.54

# centre

C2 1 0. 0. 0.

#base (x,0,-r) (-d,+-a/2,-r):x=2sqrt(2)R/3,a=4R/(6)**1/2,d=(2**1/2)*R/3,r=R/3

,R=1.54

C3 1 1.452 0. -0.513

C4 1 -0.726 1.257 -0.513

C5 1 -0.726 -1.257 -0.513

FEND

##################### FRAG #... FEND then AFIX # then AFIX 6 rigid body;AFIX Hs can be

added; AFIX 5 to mark dependent atoms afterwards.See s2932

Eg:

FRAG 17 10.331 6.322 8.52 90 90 90

C73 1 0.809000 0.861000 0.714600 11.000000 0.050000

N1 7 0.813600 0.710300 0.579300 11.000000 0.050000

O3 3 0.887600 0.748200 0.472500 11.000000 0.050000

O4 3 0.742800 0.556800 0.582800 11.000000 0.050000

FEND

PART 2 -21

AFIX 176

C73S 1 0.832023 0.191839 0.487318 -21.00000 0.03545

N1S 7 0.936135 0.264423 0.470437 -21.00000 0.03084

O3S 3 0.938637 0.305853 0.406598 -21.00000 0.05417

O4S 3 1.013437 0.278424 0.521581 -21.00000 0.05721

PART 0

AFIX 0

FRAG 18 7.9711 8.3909 9.5169 99.1945 108.748 110.617

C22 1 0.654200 -0.205400 -0.443100 11.000000 0.05000

Cl1 8 0.718700 -0.366390 -0.377580 11.000000 0.05000

Cl2 8 0.457300 -0.303900 -0.626600 11.000000 0.05000

FEND

PART 1 21

AFIX 186

C73 1 0.847481 0.233581 0.464428 21.00000 0.10272

CL1 8 0.962729 0.222324 0.535778 21.00000 0.05532

CL2 8 0.902124 0.294548 0.380703 21.00000 0.03877

PART 0

AFIX 0

Re-label Hs so unique and no longer than 4 characters

# Renumber Hs so #=>100 fit in 4 characters

gawk 'BEGIN{split("Z,Y,X,W,V,U,T,S,R,Q,P,O,N,M,L,K,J,I",lab,",");nm=0};\

!/^H[0-9][0-9][0-9]/{nm=0;print};/^H[0-9][0-9][0-9]/{a=$1;\

$1="H"substr(a,3,2)lab[substr(a,2,1)*3-nm];print;nm++}' old.res>new.res

SHELXTL & Vista

Right-click on Desktop

Click 'Personalize'

Click 'Windows Color and Appearance'

Click 'Open classic appearance properties for more color options'

Choose 'Windows Standard' and click 'Apply' and 'OK'

Twinning_&_CheckCIF

George M. Sheldrick:

Use the current (2008/4) version of TWINABS. ALWAYS merge the data when writing the HKLF 5 file with TWINABS, because it is not possible to merge these data later (eg in XL/SHELXL). Merging groups of equivalents containing different components is a non-trivial exercise and is best done by TWINABS. Note that if (as here) there are more 'observations' that there are 'unique reflections', to get the correct esds you need to set the third number on the L.S. instruction to the difference of these two numbers (they can be found at the end of the summary that is output to the console). You also need to explain to the Editor that you have done this and that he should ignore the corresponding CheckCIF warning.